Fire Sprinklers

Protection with Automatic Fire Sprinklers

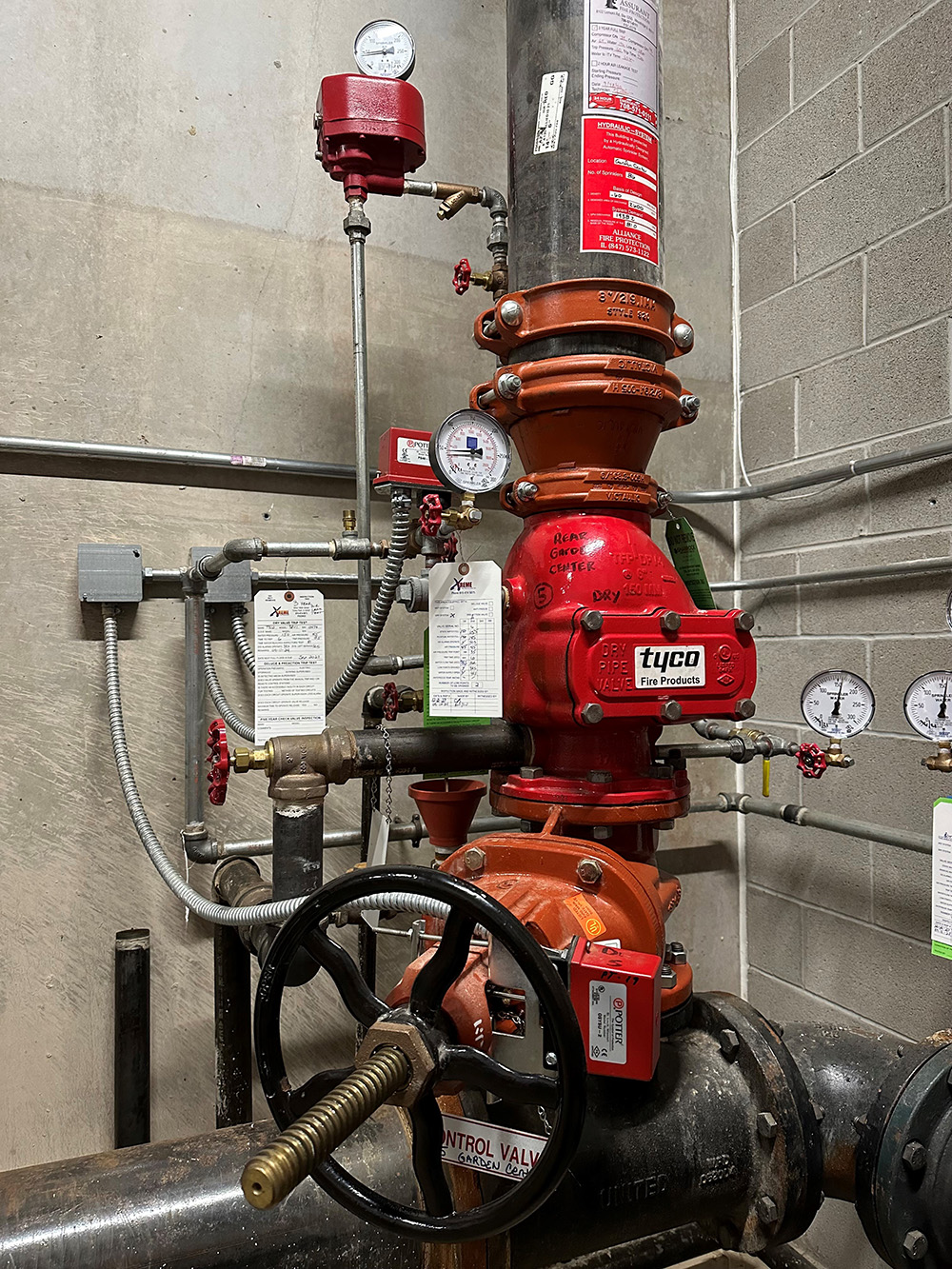

A fire sprinkler system is a crucial component of fire protection for residential, commercial, and industrial buildings. Designed to automatically detect and respond to the presence of a fire, the system consists of a network of water-filled or air-filled pipes connected to sprinkler heads strategically placed throughout the building.

Fire Sprinkler System Features

NFPA 25 Water Based System Inspection & Testing Frequency

NFPA 25, the Standard for the Inspection, Testing, and Maintenance of Water-Based Fire Protection Systems, outlines specific guidelines for how often various components of these systems should be inspected and tested to ensure they are in proper working condition. Below is a breakdown of the recommended inspection and testing frequencies for key components:

| Component | Inspection Frequency | Testing Frequency | Notes |

| Sprinklers | Annually | Quarterly (Dry Systems) | Test: Physical examination of sprinklers required every 50 years (for standard response) or 20 years (for fast-response). |

| Gauges | Monthly (Dry, Pre-Action) | 5 Years | Test: Gauge calibration or replacement required every 5 years. |

| Control Valves | Weekly/Monthly | Annually | Inspection: Ensure valves are in the correct position (open/closed). |

| Supervisory Devices | Quarterly | Annually | Test: Functional test of tamper switches and other supervisory devices. |

| Piping & Fittings | Annually | – | Inspection: Check for physical damage, corrosion, and other impairments. |

| Hangers/Braces | Annually | – | Inspection: Ensure that all hangers and braces are secure and undamaged. |

| Fire Department Connections | Quarterly | Annually | Test: Functional flow test required annually. |

| Waterflow Alarm Devices | Quarterly | Quarterly | Test: Test by opening the inspector’s test connection or by flowing water. |

| Backflow Preventers | Annually | Annually | Test: Functional test by a qualified professional required annually. |

| Pressure Reducing Valves | Annually | 5 Years | Test: Full flow test every 5 years to ensure proper operation. |

| Antifreeze Solution | Annually | Annually | Test: Test the concentration of antifreeze annually. |

Additional Notes:

- Visual Inspections: Should be performed regularly (monthly or quarterly) to ensure all components are in good condition and ready for operation.

- Record Keeping: Document all inspections, tests, and maintenance activities, including dates, persons performing the tasks, and any issues found.

- Emergency Repairs: If any deficiencies are found during inspections or tests, immediate repairs are required to ensure the system’s reliability.

This chart provides a general overview based on NFPA 25. Local regulations, manufacturer instructions, and the specific design of the fire protection system may require additional inspections and tests. Always refer to the latest edition of NFPA 25 for the most accurate and detailed information.